Plate Bearing Test

This paper presents details of a plate bearing test and report from a site visit in Kuching, Malaysia. Technical details of a plate bearing test will be presented, including standards and procedures concerned. A sample method statement will also be discussed. Photos and results from a site visit will conclude the paper.

TECHNICAL DETAILS

Introduction

The Plate Bearing Test is done when shallow foundations are to be used, or when temporary work structures such as piling rigs or cranes would be required on site. This test checks the bearing capacity of the soil near the surface of the ground. It also checks the possible settlement under a certain load. The standards applicable to this test are British Standard (BS) 1377 Part 9 and American Society for Testing and Materials (ASTM) D1194.

Frequency

The Plate Bearing Test may be done at one or several spots at a site, at the discretion of the design engineer. Sometimes, an experienced contractor may propose additional test locations which shall also depend on the engineer’s approval.

Test Setup

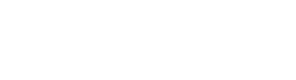

Figure 1 shows how this test is set up. Basically, it contains a plate, loading column, jack, counter weight, pressure gauge and settlement gauge.

Figure 1: Plate Bearing Test Setup

The test is done either on ground surface or in a shallow pit where the foundation would sit. The width of the pit is 4 to 5 times the plate diameter. When digging the pit, care should be taken so that the soil is minimally disturbed. An excavator without teeth is recommended, and the last 0.2m to 0.5m shall be hand-dug. Retaining structures shall be installed if necessary.

When the desired pit depth is achieved, the pit bottom is levelled as much as possible. Then, 10mm to 15mm of sand shall be placed at pit bottom to ensure the levelness of the plate as it is seated. Then, the loading column and jack will be installed above the plate, approaching the counter weight. It should be made sure that no eccentricity exists in the setup.

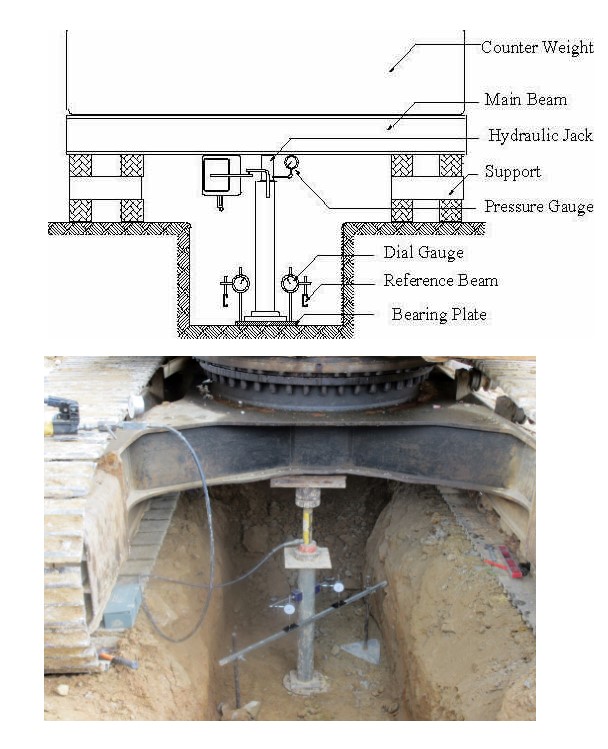

Plate diameter for this test varies from 300mm to 1000mm. It is important to note that the “stress influence zone” is twice the diameter of the plate, as shown in Figure 2.

Figure 2: Relationship between Plate Size and Stress Influence Zone

Therefore, a bigger plate is desirable when available. The bigger the plate, the better it mimics the actual conditions. The plate thickness is normally 25mm.

Loading Schedule

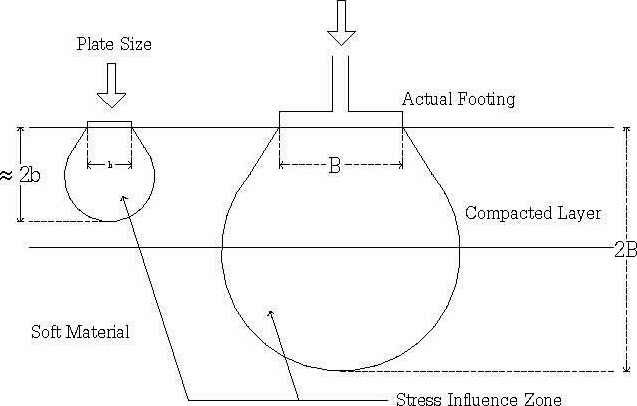

The load range that needs to be tested has to be determined. Typically, the maximum load to be tested is 2 to 2.5 times the working load, depending on the factor of safety that needs to be achieved. Loading shall be done in at least 5 more or less equally spaced increments until the maximum load is reached. Each load shall be maintained until the average settlement rate is less than 0.02mm per 5 minute interval, or until primary settlement has ceased. This can be judged from a compression vs log time plot. An example is shown in Figure 3.

Figure 3: Compression vs Log Time

It can be seen that primary consolidation ends when the settlement rate begins to slow down towards the end of the cycle. A turning point exists when primary consolidation ends and secondary consolidation begins.

Table 1 shows a sample loading step where the working load is 200 kN/m2. The maximum load to be tested is 2.5 times the working load.

| Working Load: 200 kN/m2 | ||||

| Max. Load: 500 kN/m2 | ||||

| Loading (% of working load) | 0, 25, 50, 75, 100, 125, 150, 175, 200, 225, 250 | |||

| Unloading (% of working load) | 200, 150, 100, 50, 0 | |||

Table 1: Sample Loading Steps

In this loading schedule, the load is increased by 25% or 50 kN/m2 until it reaches the maximum load to be tested, which is 500 kN/m2. Each load is held at constant pressure for 15 minutes. Then, unloading is done by reducing the pressure by 50 kN/m2 every 15 minutes.

Allowable Settlement

The allowable settlement has to be determined by the design engineer. Although the soil’s bearing capacity might be satisfactory, caution has to be taken that the settlement is within allowable range. If the soil sinks rapidly, it is deemed to have passed its ultimate bearing capacity.

The ultimate bearing capacity is sometimes considered as the load at which settlement of 25mm occurs. The allowable bearing capacity, with a factor of safety of 2, would be one half of the ultimate bearing capacity.

ASTM vs BS

The American and British standards for the Plate Bearing Test are similar. However, there are some differences that will be discussed here. According to ASTM, the width of a test pit being dug has to be at least 4 times of the plate diameter. However, BS says this width has to be limited between 4 to 5 times the plate diameter.

ASTM also says that the plate diameter or width is between 300mm – 1000mm. BS specifies 300mm – 600mm.

Key Points

When conducting plate bearing tests, it is important to note the following:

- Frequency of test – Sufficient number of tests should be conducted for each project site

- Plate size – Bigger plates are desirable when available since the effective depth tested is only twice the plate diameter

- Preparation of test pit – Minimal disturbance to test pit is required for accurate results

- Range of test load – A suitable factor of safety will determine the maximum load to be tested

- Allowable settlement – Although the bearing capacity might be adequate, excessive settlement will deem failure of the soil

SAMPLE METHOD STATEMENT

The method statement presented here is the one used at the site visited.

Standard used

ASTM Test D1194-72 – Standard Test Method for Bearing Capacity of Soil for Static Load and Spread Footing.

Instruments

Loading Jack: 10 tonnes hydraulic (Enerpac RC106)

Pressure Gauge: 0 – 10,000 psi

Settlement Gauge: 0 – 50mm with 0.01mm least count

Plate: 300mm diameter

Test Criteria

Working Load: 200 kN/m2

Maximum Load on Plate: 400 kN/m2

Preloading bearing pressure before actual testing: 20 kN/m2

Test Setup

- The test pit and reaction load which is sufficiently more than the test loads are prepared.

- The bottom surface of the pit shall be levelled and the plate is placed at the centre over an evenly spread sand bed of not more than 10mm.

- Loading column of sufficient length shall be placed at the centre of the plate and the jack shall be set at the top of the loading column without any eccentricity to the reaction load.

- Two settlement gauges with magnetic bases are positioned diagonally over the edges of the plate. These gauges will measure settlement with reference to a datum bar supported away from the load influence zone.

Loading Schedule

The table below shows a loading schedule where the working load is 200 kN/m2 and the maximum load is twice the working load. At maximum load, the pressure is maintained for 3 hours.

| Working Load: 200 kN/m2 | |||||

| Max. Load: 400 kN/m2 | |||||

| Increment Load as % of Working Load (%) | Bearing Pressure (kN/m2) | Applied Load for 300mm dia. Plate (kN) | Jack Gauge Reading (psi) | Minimum Holding Time (Minutes) | Remarks |

| 10 | 20 | 1.41 | 141 | 0 | Preloading bearing pressure |

| 25 | 50 | 3.53 | 352 | 15 | Reading shall be recorded at 5 minute intervals for the first 15 minutes and at 15 minute intervals thereafter. |

| 50 | 100 | 7.07 | 705 | 15 | |

| 75 | 150 | 10.60 | 1057 | 15 | |

| 100 | 200 | 14.14 | 1409 | 15 | |

| 125 | 250 | 17.67 | 1762 | 15 | |

| 150 | 300 | 21.21 | 2114 | 15 | |

| 175 | 350 | 24.74 | 2466 | 15 | |

| 200 | 400 | 28.27 | 2819 | 3 hours | |

| 150 | 300 | 21.21 | 2114 | 15 | |

| 100 | 200 | 14.14 | 1409 | 15 | |

| 50 | 100 | 7.07 | 705 | 15 | |

| 0 | 0 | 0 | 0 | 15 | |

|

Total |

5 hrs 45 mins | ||||

Table 2: Test Loading Schedule

SITE VISIT

Below are a few points I would like to discuss from the site visit. The site was located at 9th mile, Kuching. It was a commercial shop lot project. The visit was made in the morning of 12 February 2014.

Test Pit

The test pit was dug using an excavator with teeth. After excavating to the approximate depth required, the operator was asked to lightly compact the soil with the excavator bucket. Then, the excavator was parked above the pit as the counter weight.

One problem faced here was that the pit depth was not accurate enough. Therefore, the excavator operator had to re-dig several times, delaying the test. In my opinion, the testing company should have dug the last 0.2m-0.5m manually using a spade to achieve the desired depth. Alternatively, suitable extensions could have been used to adjust the height of the loading column set up. Also, by using the bucket with teeth, the soil in the pit would have loosened. This will affect the settlement readings. Thus, digging the last few hundred millimetres manually is highly recommended so as to minimise soil disturbance.

Plate Size

A round plate with a diameter of 300mm was used in this test. Therefore, the effective depth tested was up to 600mm beneath the test pit. This seems quite shallow. Therefore, it is important that the test pit is being dug to the level where the footing might sit. However, when large plates exists, they are always desirable.

Loading Schedule

The loading schedule as in Table 2 was used at this site. The working load was 200 kN/m2, and the maximum load tested was 400 kN/m2.

Test Results

The test results are tabulated as follows:

Table 3: Test Results

| Bearing Pressure (kN/m2) | Applied Load for 300mm dia. Plate (kN) | Jack Gauge Reading (psi) | Maximum Settlement (mm) |

|

50 |

3.53 |

352 |

0.77 |

|

100 |

7.07 |

705 |

1.49 |

|

150 |

10.60 |

1057 |

4.95 |

|

200 |

14.14 |

1409 |

7.99 |

|

250 |

17.67 |

1762 |

16.99 |

|

300 |

21.21 |

2114 |

27.05 |

|

350 |

24.74 |

2466 |

29.85 |

|

400 |

28.27 |

2819 |

35.77 |

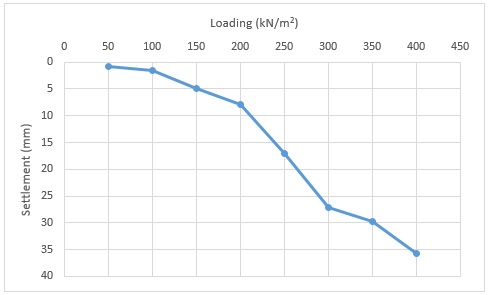

The test was stopped at the bearing pressure of 400 kN/m2 without proceeding with unloading because the settlement had exceeded the allowable limit of 30mm, which was predetermined by the design engineer. At 350 kN/m2, the settlement was 29.85mm and at 400 kN/m2 the settlement had increased to 35.77mm. We can therefore deduce that the ultimate bearing capacity is approximately 350 kN/m2 and the allowable bearing capacity (with a Factor of Safety of 2) is 175 kN/m2. The loading vs settlement graph is plotted below.

Figure 4: Loading vs Settlement

From the graph, it can be seen that between 100 kN/m2 to 200 kN/m2 and 300 kN/m2 to 400 kN/m2, the settlement rate was about the same. Between 200 kN/m2 to 300 kN/m2, the settlement rate was slightly higher. This implies that as soon as construction completes, a higher settlement rate would be experienced if additional loads are added.

CONCULSION

The Plate Bearing Test is done when shallow foundations are to be used, or when temporary work structures would be used at a site. It checks the bearing capacity of the soil and possible settlement at a given load. Caution has to be exercised when following test standards. Factors to be considered by the engineer include number of tests needed at the site, load range to be tested, size of the plate, and allowable settlement.

In some cases, although not recommended, the design engineer has to modify the standard procedure to suit local conditions. Nonetheless, sound judgment is needed whenever deviations from the standards are deemed necessary.

APPENDIX

Test pit excavation

Site supervisors and testing crew inspecting work in progress

Pit preparation – laying of sand to ensure levelness at the bottom of the pit for test plate and loading column to sit on

A tarpaulin is used to cover the apparatus from inclement weather

You can download the full report here: Plate Bearing Test Paper